Why finfish seed production was unsuccessful in Chile.

Why finfish seed production was unsuccessful in Chile

Masatoshi FUTAGAWA

CORDUNAP

February 24,

2012

There were many

finfish seed production projects for decades and majority were failure, a few

had produced or none. I have some points of view about the reasons why. Major

problem is nutrition of rotifer, particularly feeds for rotifer.

1. Rotifer culture and handling

1.1. Nutritional value

Rotifer

is commonly used for primary live feeds for fish larva. Chile fish seed

production use rotifer which is cultured by bread yeast (SMC, Saccharomyces cerevisiae, 4-7 µm) or marine chlorella (NCO, Nannochloropsis oculata, 2-6 µm) and feed to fish larva after enrichment. Besides, it is cultured

by concentrated freshwater

chlorella

(CCV12, Chlorella vulgaris, 2-10 µm, 12 billion cells/ml, vitamin

B12 soluble) and NCO. Then it is fed to larva after enrichment in Japan. In 2006, 51 % of

hatchery use CCV12 and 92 % use CCV12 and NCO.

Additionally,

according to study shows that SMC fed

rotifer were totally dead until 3rd generation, SMC fed at 1st

generation and NCO from 2nd generation show 20 % lower survival, development

time and spawning interval were 1.1 and 1.2 times lower accordingly compare to feeding

NCO rotifer. These results suggest that the effect of material diet influenced

even next generation by affecting the quality of eggs. Thus, nutritional value

of rotifer was low in Chile.

1.2. Size

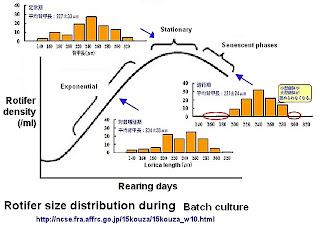

Usually

larva can take 25 to 50 % of mouth size rotifer and according to study, rotifer size composition change,

average size not much change, depending on rotifer condition. Particularly,

during senescent phases rotifer has no small and big size composition. It will

happen if we feed rotifer during senescent phase, larva has not enough rotifer

even feed correct quantity.

1.3. Tolerance

According

to paper those rotifers (L

and S-types) tolerate water temperature changing to maximum 5 ̊C and salinity increase

from 26 to 33 pus. For example, if rearing larva in 16 ̊C, it should enrich rotifer

below 21 ̊C and rearing below 26 ̊C. Also, salinity in larva tank shows 35 psu,

enrichment water should be more than 28 psu and rotifer culture water should be

over 21 pus approximately.

2. Rotifer culture in Japan

2.1. History

In

the start of rotifer culture, late 60’s, we fed NCO which required huge outdoor

tanks for culture, lot of manpower and land for culturing. Also fed SMC for substitute

feeds in early 70’s but they found that the rotifer lacked nutrition, larva had

low survival and mal pigmentation even when fed NCO. Then enrichment materials

were invented and applied after feeding NCO in 70’s. CCV12 was invented which fulfilled

nutritional requirement and production activity was drastically minimized in

late 80’s.

Three

types of rotifer are cultured in Japan, L-type (Brachionus plicatilis), S-type (B. rotundiformis) and SS-type, which are

fed CCV12. Detail of rotifers culture as below.

2.2. Extensive continuous rotifer culture method (ECRC)

There are four culture methods; Batch

culture, Partial harvest culture, High density culture and Extensive Continuous

Rotifer Culture (ECRC), are operating in Japan. ECRC method was invented

lately and produces better quality of rotifer compared

to Batch culture in terms of nutrition value and size distribution. Also, the

method makes larva strong with high survival and it is operating at 49 % of

hatchery in Japan in 2007.

The concepts of ECRC are sustainable stable

production with less work activities such as feeding, filter washing and tank

cleaning under mass production.

ECRC consist two duplicate large tanks, culture

tank and harvest tank, which equipped of four air stones in each bottom corner

and both tanks are connected by siphon hose, collecting box to gather rotifer

by fine mesh bag-net, feeds tank with metering pump to feed CCV12 continually,

fresh and sea water supply to add water continually.

Advantages

of this system are as follows.

- · Continues water supply allow to long term culture, over a month, due to diluting ammonia and bacteria.

- · Long term culture minimizes work activities such as washing tank and restocking.

- · Stable production due to constant water supply and harvest.

- · Active and wide size rotifer production at exponential and stationary phase due to stable water condition.

- · No filter material required due to slow aeration makes particles settle on bottom easily.

- · Easy to detect rotifer condition that shows density reduction.

- · Harvest tank switch to culture tank, rearing tank become harvest tank, to reverse current direction when productivity down and a culture continue.

Disadvantage

is that the system requires large tanks

Actual

operation shows that fresh water and sea water supplied to culture tank (25 Kl)

continuously, water exchange rate 50 % (12.5 Kl), and rearing water controlled

to WT 20 ̊C and Sa 20 pus. Water supply volume depends on growth rate of rotifer which

flow-out to harvest tank to keep rotifer density 120 rotifer/ml. CCV12 fed

continuously as volume of 6 L per day (6 ml/106L-type) and harvest 600

million rotifer a daily from Day4 under 35 days culture period.

There

are two important points to operating ECRC which maximum water exchange and controlling

rotifer growth to adjust feeds. Water supply maintains water quality of system and

water volume related to growth rate (water volume = rotifer growth) which

depend on WT and Salinity as shown in the table below. However, those factors are

not much different to rearing water of larva to minimize a rotifer shock. Thus,

you should find ideal WT and Sa to meet maximum growth which related larva

culture water.

Second

point is it should give 70 % of maximum feeding (5 ml/106L-type or

1.5 ml/106S-type) to limit growth. Because when feeding maximum, the

growth fluctuate due to variable water supply and feeds quantity, it happen

during operation usually. Once it happen

it is difficult to recover. In the other hand, under feeding rotifer density settles

to particular number which depends on availability of feeds without corruption

of culture.

2.3. ECRC and SISP combination

Recently,

ECRC in combination with SISP (Semi Intensive Seed Production) and seed quality

and survival improve with sea bream and black rockfish

(49-55).

The method shows that larva culture at

harvest tank of ECRC with or without enrichment rotifer. The advantages are

produced strong larva, grow fast with less work activities compare to intensive

method.

3. Suggestion

Concentrated fresh

water chlorella (CCV12) is the key item to prepare nutritious rotifer, produce strong

fish larva. Unfortunately, CCV12 is not available in Chile. Bellows are my

suggestions.

- Import CCV12; CCV12 is not much expensive material but problem is to keep the material fresh, keep in cold storage and it should be consumed within a month once open bottle. Possibly, combine orders to make large quantity and minimize freight, deliver under cold chain just after arrive in Chile.

- Dry microalga; Skretting (ORI-GO culture or green) and Biomarine (Algamac protein plus) supply dry micro alga as a substitute of CCV12. Advantage is longer life than fresh material. However, it needs to improve usage.

- Semi intensive seed production method (SISP); The method is culture wild copepods in large outdoor tank and produce larva together, feed un-enriched rotifer and Artemia depending on availability of copepods sometime. The method will version up to recirculation SISP (RESISP) and improve survival rate.

Comments

Post a Comment